Loose lay floors should be installed in accordance with these instructions as well as the applicable national standards and building codes for the installation of resilient flooring at the time of installation, to ensure a quality fit. These floors are not suitable for installation outdoors or in rooms that will be continually wet. They are suitable for use in traditional residential bathrooms^, kitchens, laundry / utility rooms.

Failure to observe and follow these installation guidelines and / or current national standards and building codes at time of installation may result in any potential warranty claim being void.

It is recommended that when selecting flooring products, you verify compliance with building regulations and certification practices relevant to your local area

National standards and building codes

- Australia and New Zealand: AS / NZS 1884

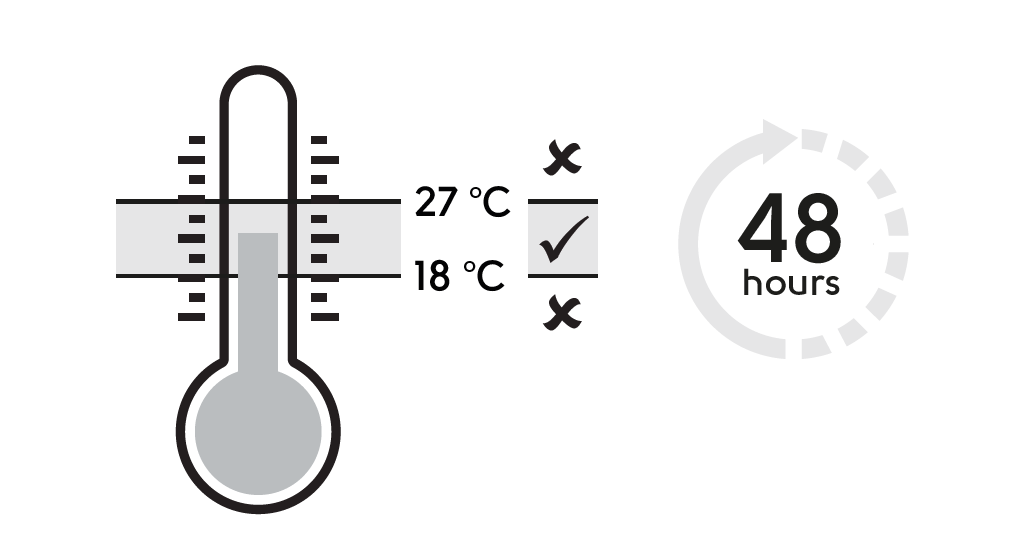

Flooring materials should be removed from packaging at least 48 hours prior to installation and allowed to condition in the room where installation is to take place (tiles / planks may be stacked but must be rested flat). HVAC systems, where available, should be in operation during the acclimatisation period (at least 48 hours prior to, during, and 24 hours after installation of floor coverings). Exposure to direct sunlight should be avoided during the acclimatisation and installation process by means of window coverings or temporary measures.

For optimum performance, room temperature should always be maintained between 18-27°C.

Subfloor preparation must comply with applicable national standards and building codes for the installation of resilient flooring at time of installation and in strict accordance with these installation guidelines.

The subfloor must be firm, hard, flat, level, smooth, dry, clean and dust-free and should be prepared dependent on your subfloor type. Subfloor must be porous when using water-based hard set adhesive. See section “Types of Subfloor” for details.

Moisture of the base subfloor (e.g. concrete) must be measured according to the relevant local standard:

- Hygrometer test (primary test method ASTM F2170) = less than 95% RH.

- Calcium chloride test (secondary test method ASTM F1869) = no more than 15mg/m² moisture per 24 hours.

Moisture of the base subfloor (e.g. timber, ply and particleboard) must be measured according to the relevant local standard:

- Timber and particleboard subfloors (test method AS/NZS 1080.1) = 10% - 14%

- Plywood subfloors (test method AS/NZS 2098.1) = 10% - 14%

If any subfloor shows moisture readings above these values, an appropriate damp proof membrane (DPM) or moisture suppression system must be used.

NOTE: Some national standards require the pH of the concrete slab to be controlled.

The 95% RH value is applicable to the loose lay only. Consult with underlay, underlayment and adhesive manufacturers for compatibility with the humidity levels of your subfloor.

The design on this product is randomly distributed and can be heavier on some tiles / planks than others. To prevent heavy and light color shading areas, the tiles / planks should be unboxed and shuffled.

Loose lay can be installed using one of the following methods, led by the environmental conditions of the interior space where the floor is to be installed.

Separate underlay is normally only recommended for subfloor floor rectification and / or acoustic purposes.

Please consult with supplier for approved underlay systems.

Loose lay must NOT be installed over cushioned vinyl or non-approved underlay; these must be removed and the subfloor treated and prepared to the applicable standard.

1. Grid stick method using Karndean Hi Tack or similar pressure sensitive adhesive

Light foot traffic, non-commercial, stable in-room climate**

Check that all room edges are solid. Apply a 10cm strip of Karndean Hi Tack or similar adhesive to all perimeter walls and door thresholds with an appropriate application method and spread rate (VI notched trowel) as per adhesive manufacturer's installation guides. Add further 10cm strips of adhesive at intervals of 4m parallel to each perimeter wall, creating a grid pattern.

Adhesive must be allowed to fully tack off before installation.

Tiles / planks must be fitted tight to the wall, and to each other, across the whole room.

2. Full coverage using Karndean Hi Tack or similar pressure sensitive adhesive

General foot traffic, light commercial and stable in-room climate**

Check that all room edges are solid. Apply Karndean Hi Tack or similar adhesive to all floor areas with an appropriate application method and spread rate (VI notched trowel) as per adhesive manufacturer's installation guides. Adhesive must be allowed to fully tack off before installation.

Tiles / planks must be fitted tight to the wall, and to each other, across the whole room.

3. Full coverage using hard-set adhesive

High foot traffic, commercial and unstable in-room climate**

Recommended for commercial and environments with an unstable climate**

Please refer to separate LVT gluedown installation guidelines for subfloor requirements, preparation and installation procedure.

Please refer to separate LVT gluedown installation guidelines for subfloor requirements, preparation and installation procedure.

4. Full coverage using 2-part chemical cure or similar water and heat resistant adhesive

High spillage wet areas, sunrooms, conservatories, panoramic windows.

Recommended for areas that are likely to be subject to high water spillage or extreme temperature fluctuations.

Please refer to separate LVT gluedown installation guidelines for subfloor requirements, preparation and installation procedure.

** Stable in-room climate = rooms where a low rate of temperature fluctuation is expected in any 24-hour period. Where it is anticipated that internal temperatures could have a variation of 15°C or more, the area should be considered as having an unstable climate and the use of a hard-set adhesive system be adopted.

- Any primer, levelling compound or other underlayment should be installed in accordance with instructions from that manufacturer.

- No responsibility will be accepted for any subfloor or joint show through to the installed product, either as a “ridge” or a “valley”.

- Warning: solvents and other abrasive chemicals used to clean or remove subfloor contaminants can damage the backing of loose lay and affect the product’s performance.

Old adhesive residues

All adhesive residues from previous installations must be mechanically removed. No chemical adhesive removers are allowed on a concrete substrate.

NOTE: Any contaminants left on the surface of the subfloor may adversely affect future adhesion or cause discolouration.

Concrete floors

Subfloors / Screeds: All cracks and joints must be filled using a suitable repair system and the floor needs to be level in accordance with the applicable standard.

Any gypsum (anhydrite) based floors must be sealed with a compatible sealing compound.

Mosaic / terrazzo / ceramics / quarry tiles

Ensure surface is firm, dry and free of wax, oil, dust and loose tile particles. Apply an appropriate primer and levelling compound, ensuring that all grout lines are filled and levelled.

Timber, particle floors and OSB (Oriented Strand Board)

These should be solid with minimal flexibility. All loose boards must be firmly fastened, gaps filled and undulations removed. Overlay floorboards, particle board and OSB with flooring grade plywood or similar.

Thermoplastic / woodblock / parquet

Make sure these floors are solid, sound and in good condition. Remove or repair loose, broken or damaged

areas and remove any surface polish / sealer.

These products should be removed if installed directly to earth / the ground (no DPM), or over bitumen / cutback / ATA or pitch. Wood in direct contact with concrete must be removed before installation of floor covering.

Then prepare exposed subfloor to the applicable standard.

Laminate / hybrid / EPC / SPC / engineered timber or other floating floor

These are to be removed including any underlays. Then assess and prepare the exposed subfloor to the applicable standard.

Linoleum / sheet vinyl

Loose lay can be installed over these products, as long as they are sufficiently resistant to indentation (cushioned vinyl for example will not be acceptable). Only installation method 1 or 2 should be used, provided the surface is securely fixed and cleaned to remove all contamination including polishes and dressings.

If floor is soft and / or prone to indentation, or there are any doubts, removal of the floor including any underlay is recommended. Then assess and prepare the exposed subfloor to applicable standard.

Metal and painted floors

Fully remove any loose paint or other finishes.

Raised access floors

Ensure raised access panels are firm, level, smooth, clean and free from defects and contaminants. Raised access panels should be in accordance with local building standards: gaps between panels should not exceed 1mm; the overall floor to be level within 1.5mm over a 5m radius; unstable, uneven or poor-quality panels should be suitably repaired prior to installation; tiles should be set out such that their edges do not fall on or close to the edge of the raised access panel.

Other floors

Please consult your supplier.

Loose lay flooring is suitable for use over underfloor heating systems, but these must be controlled to keep the interface between the subfloor surface and the backing at no more than 27°C.

The system must be switched off 48 hours before, during, and for 48 hours after the installation, then temperature gradually increased by no more than 2°C per day to desired warmth.

The room temperature must be between 18-27°C prior to and during installation.

Electrical underfloor heating: please consult manufacturer to ensure their system is compatible with this flooring.

Mesh / wire systems: must be installed according to manufacturer instructions, embedded into a base coat of appropriately reinforced smoothing compound in consultation with the selected underfloor heating manufacturer.

IMPORTANT: Care must be taken to avoid damage to the floor caused by localised hot spots. Particular consideration must be given in placing rugs and items of furniture which do not allow hot air circulation. No responsibility for damage to floor tiles / planks can be accepted under these circumstances.

- Use entrance mats to protect against grit and moisture.

- Ensure mats and rugs are not rubber-backed (and of a non-staining variety) to prevent any discolouration of the floor.

- Avoid sliding or dragging furniture or other objects across the floor - use floor protector pads to prevent scratching.

- Use large castor cups or other means to protect against indentation from heavy furniture.

- Regularly sweep the floor to remove loose dirt or grit as these can cause fine scratches.

- For a thorough clean, a range of pH neutral cleaning materials are available. Avoid the use of household cleaners and bleach-based detergents. These could make the floor slippery or cause discolouration.

- Always mop up spills as soon as possible to reduce the risk of slipping and possible staining.

- Do not subject loose lay to standing water. This will present a slip hazard.

- Floor care guides are available from your supplier or the website.

AUS: 1800 331 170

NZ: 0800 442 101

Email: technical@karndean .com.au