Gluedown floors should be installed in accordance with these instructions as well as the applicable national standards and building codes for the installation of resilient flooring at the time of installation, to ensure a quality fit. These floors are not suitable for installation outdoors or in rooms that will be continually wet. They are suitable for use in traditional residential bathrooms, kitchens, laundry/utility rooms.

Failure to observe and follow these installation guidelines and / or current national standards and building codes at time of installation may result in any potential warranty claim being void.

National standards and building codes- United States and Canada: ASTM F710

It is the responsibility of the installer to visually inspect all materials in optimal lighting to confirm it is the correct design, colour, batch, quality, free from defects and quantity as ordered. If the material or batching is incorrect or where defects are apparent, the store of purchase must be contacted before the material is installed. Complaints and claims regarding clearly identifiable defects will not be accepted after installation. Preparation and installation should not begin until all other trades have completed their work.

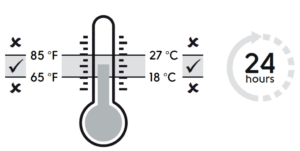

Flooring materials should be removed from packaging at least 24 hours prior to installation and allowed to condition in the room where installation is to take place (tiles / planks may be stacked but must be rested flat). HVAC systems, where available, should be in operation during the acclimation period (at least 24 hours prior to, during, and 24 hours after installation of floor coverings). Exposure to direct sunlight should be avoided during the acclimation and installation process by means of window coverings or temporary measures.

For optimum performance, room temperature should always be maintained between 65-85°F* (USA) or 18-27°C (Canada).

Subfloor preparation must comply with applicable national standards and building codes for the installation of resilient flooring at time of installation and in strict accordance with these installation guidelines.

The subfloor must be firm, hard, flat, level, smooth, dry, clean and dust-free and should be prepared dependent on your subfloor type.

See section Types of subfloor for specific preparation guidelines.

Moisture of the base subfloor (e.g. concrete) must be measured according to ASTM F1869 (Calcium Chloride) or ASTM F2170 (RH). The moisture limits for Karndean gluedown floors are mandated by the limits of the adhesive used. Our adhesive limits are as follows:

- Karndean K-99 HM 11lbs. (Calcium Chloride) 99% (RH)

- Karndean DrySet 8lbs. (Calcium Chloride) 95% (RH)

- Karndean K-Spray 10lbs. (Calcium Chloride) 98% (RH)

- Karndean 2-part Epoxy 8lbs. (Calcium Chloride) 90% (RH)

NOTE: Wood subfloors should be checked and measured for moisture not to exceed 13%.

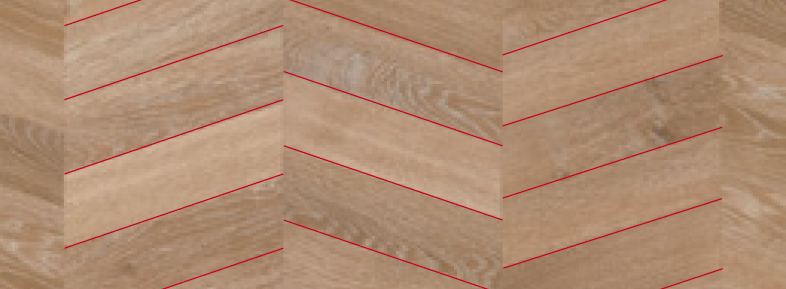

The design on this product is randomly distributed and can be heavier on some tiles / planks than others. To prevent heavy and light colour shading areas, the tiles/planks should be unboxed and shuffled.

- Open several boxes of material.

- Separate the lefts and rights into stacks.

- Ensure a staggered laying pattern when installing your floor.

NOTE:

- The chevron pieces within the plank are not intended to align on either the short or the long edges.

- If installed alongside our corresponding non-chevron plank product, standard colour batch variation rules apply.

- Lay the tiles and planks into adhesive that has fully tacked, without exceeding adhesive open time, to ensure maximum bond strength and minimize the risk of peaking and gapping.

- Use a hand roller for each small section immediately as you progress. Wipe excess adhesive off immediately with a damp cloth.

- The whole area should be rolled in both directions after installation using a 100 lb roller or a hand roller in confined areas, paying particular attention to the edges.

- Refer to selected adhesive instructions for proper cure time and any traffic restrictions.

- Clean-up surplus adhesive following manufacturer guidelines. For most adhesives, it is recommended that they are removed while still wet, using a damp cloth. Dry adhesive can be removed using detergent and water or mineral spirits.

- Maintain climate conditions as per acclimation process after installation.

NOTE: the company will not be liable for any loss, damage or complaint if the incorrect installation method or adhesive system is adopted for the installation, and / or the adhesive manufacturer’s instructions are not strictly followed.

1. Solid subfloors ASTM F710

Concrete/sand cement screeds

These subfloors must comply with ASTM F710.

New and old

For all concrete floors, mechanically abrade the floor to remove contamination (laitance, paint, plaster, adhesive etc). Prepare the floor to ASTM F710. If necessary apply a suitable damp proof membrane system in accordance with the product manufacturer’s instructions.

Power floated concrete

After using a water drop test (per ASTM F3191) to determine porosity (beading of water droplets), mechanical abrasive preparation either via diamond grinding, scarification or light shot blasting may be necessary to remove laitance and allow adhesive to disperse into the substrate. Where moisture values exceed the above limits, these surfaces must still be abraded before the application of a suitable damp proof membrane / moisture suppression system.

Gypsum (Anhydrite)

Gypsum must be sealed / primed with a product manufactured to seal / prime gypsum in order to accept resilient adhesives.

Painted floors

Mechanically remove all paint back to the original base. Assess and treat as per the exposed subfloor.

2. Wood subfloors ASTM F1482

All chipboard / particleboard / Weyroc / MDF / OSB

Overlay with a ¼” underlayment / flooring grade plywood or panels manufactured as underlayment for resilient flooring. Plywood joints should be smoothed over using cement-based skim coat / patch or using an appropriate primer and cement-based levelling compound by consulting your underlayment supplier. Plywood must be fixed according according to manufacturer’s instruction and ASTM F1482 to eliminate potential movement later from changing climatic conditions. Underlayment grade plywood floors Plywood joints should be smoothed over using cement-based skim coat / patch or using an appropriate primer and cement-based levelling compound. For any plywood floors with thickness less than ¼”, treat as chipboard.

Underlayment grade plywood floors

Plywood joints should be smoothed over using cement-based skim coat/patch or using an appropriate primer and cement-based levelling compound. For any plywood floors with thickness less than ¼”, treat as chipboard.

Standard floorboards / OSB

Floorboards should be well secured, loose boards firmly fastened, and worn / broken boards replaced. Install a minimum ¼” underlayment / flooring grade plywood, fixed according to manufacturer’s instruction and to ASTM F1482. Plywood joints should be smoothed over using a cement-based skim coat / patch or alternatively a suitable primer and cement-based levelling compound.

Undulating wood plank floors

These should first be levelled, by sanding or planning to remove undulations. Then overlay with flooring grade

¼” plywood, using a cement-based floor patch, fill in the plywood seams and fasteners.

Alternatively, a suitable primer and cement-based self levelling compound may be used for patch-filling prior to installation of plywood.

Wood mosaic panel, woodblock, wood strip

Any wood products directly adhered to concrete must be removed prior to installation of any resilient flooring. Wood products attached to a wood substrate can be overlaid with flooring grade ¼” plywood. Using a cement-based floor patch, fill in the plywood seams and fasteners per patch manufacturer’s instructions.

Laminate, click together, or any floating floor

These floor coverings must be removed together with any underlay and flooring accessories. The subfloor should be treated appropriately.

3. Other existing subfloors

Asbestos

Some older resilient tiles and adhesives can contain asbestos. Asbestos and asbestos adhesive residue must be mechanically removed by a professional abatement company prior to installing any LVT. In case of doubt contact the relevant authority for advice on removal and disposal.

Metal Floors

The metal surface should be cleaned, degreased and then mechanically abraded to remove contamination / rust and provide a surface key. Where this gives a level surface, the floor covering should be adhered with Karndean’s 2-part epoxy.

Quarry tile / mosaic / terrazzo / porcelain / ceramics

Test floor for evidence of damp. If dampness is detected consult your supplier.

In most cases these substrates will not be sufficiently absorbent for the adhesive to disperse into the substrate. These should either be removed, and the subfloor prepared and treated as per the exposed subfloor, or mechanically prepare the surface by thoroughly cleaning, rinsing and abrading the surface, taking extra care to ensure that the surface is firm, dry and free of wax, oil, dust and loose tiles / fragments and that all holes are repaired with a suitable fast-set repair mortar. Apply an appropriate primer & levelling compound by consulting your underlayment supplier, ensuring that all grout lines are filled with no show-through. A second topcoat of primer and levelling compound may be required to smooth over old tile grout lines.

Resilient floor coverings e.g. linoleum, PVC, thermoplastic

If you have one layer of well adhered, non-cushioned, stable, existing flooring VCT, vinyl, LVT, ceramic tile, stone or terrazzo, you may install directly over these properly prepared floors. All sealers or waxers must be removed, and any necessary floor preparation must be performed prior to installation of LVT.

Cork, carpet

Remove existing floor covering and all traces of adhesive residues. Then treat the subfloor appropriately.

(Sunrooms / Conservatories / areas adjacent to panoramic or floor to ceiling glazing / unheated rooms / high spillage wet areas).

Where surface temperatures up to 122°F (50°C) are expected, our recommended adhesive must be used. In areas where a surface temperature more than 122°F (50°C) is possible, or high spillages and repeated wet conditions, the floor must be installed with Karndean 2-part epoxy. It is necessary to keep the ambient temperature in these areas at 65-85°F (18-27°C) for 24 hours prior to, during, and 24 hours after installation. Shade windows prior to and at least 48 hours after installation.

Planks / tiles may be installed over underfloor heating systems, but these must be constructed so that the temperature at the adhesive interface does not exceed 85°F (27°C)³ ensuring the correct adhesive is used. The underfloor heating must be commissioned before installation commences. It should then be switched off 48 hours before, during, and 48 hours after installation. The temperature can then be gradually increased to 85°F (27°C)³ at no more than 4°F (2°C) per day to the desired temperature.

Electrical underfloor heating: please consult manufacturer to ensure their system is compatible with this flooring. Mesh / wire systems must be bedded into a base coat of appropriate primer & levelling compound to cover the wires or mesh by consulting your underlayment supplier.

The room temperature must be between 65‑85°F (18°C‑27°C)³ prior to and during installation, for both concrete and timber subfloors.

For underfloor heating pipes set into concrete, prime the surface before applying a compatible levelling compound as per the manufacturer’s instructions.

IMPORTANT: Care must be taken to avoid damage to the floor caused by localised “hot spots / thermal blocks”. Consideration must be given in placing rugs, and items of furniture which do not allow hot air circulation. No responsibility for damage to floor tiles can be accepted under these circumstances.

- Use entrance mats to protect against grit and moisture. Ensure they are not rubber-backed (of a non-staining variety) to prevent any discoloration of the floor.

- Avoid sliding or dragging furniture or other objects across the floor – use floor protector pads to prevent scratching.

- Use large castor cups or other means to protect against indentation from heavy furniture.

- Regularly sweep the floor to remove loose dirt or grit as these can cause fine scratches.

- For a thorough clean, a range of pH neutral cleaning materials are available. Avoid the use of household cleaners and bleach-based detergents. These could make the floor slippery or cause discoloration.

- Always mop up spills as soon as possible to reduce the risk of slipping and possible staining.

- Do not subject this flooring to standing water. This will present a slip hazard.

- Floor care guides are available from your supplier or the website.